ULTRASONIC TESTING

Ultrasonic Testing or UT

Compactness control method allowing the detection of a defect inside the material.

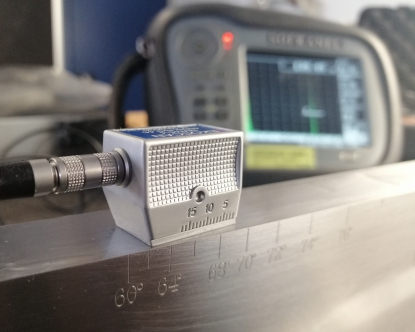

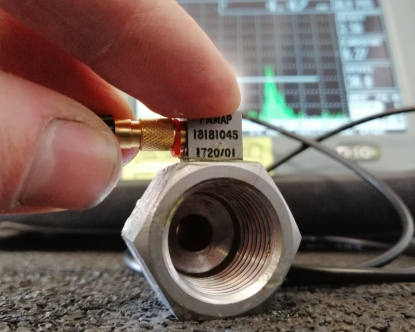

Ultrasonic waves are sent through the material by means of a transducer, composed of a piezoelectric element. The waves propagate through the material until they meet an interface, or change material and return part of their beam back to the transducer. The ultrasonic tester converts these reflections into signals on an oscilloscope display.

The controller then interprets the different signals (called echoes or peaks) according to their amplitude, duration and distance in the controlled material. The type of wave used and the grade of the material under examination must be taken into account.

This method is applied on most steels (exception for austenitic stainless steels, which require special training), in particular for weld inspection and thickness measurement to detect tube corrosion.

Compactness control method allowing the detection of a defect inside the material.

Ultrasonic waves are sent through the material by means of a transducer, composed of a piezoelectric element. The waves propagate through the material until they meet an interface, or change material and return part of their beam back to the transducer. The ultrasonic tester converts these reflections into signals on an oscilloscope display.

The controller then interprets the different signals (called echoes or peaks) according to their amplitude, duration and distance in the controlled material. The type of wave used and the grade of the material under examination must be taken into account.

This method is applied on most steels (exception for austenitic stainless steels, which require special training), in particular for weld inspection and thickness measurement to detect tube corrosion.